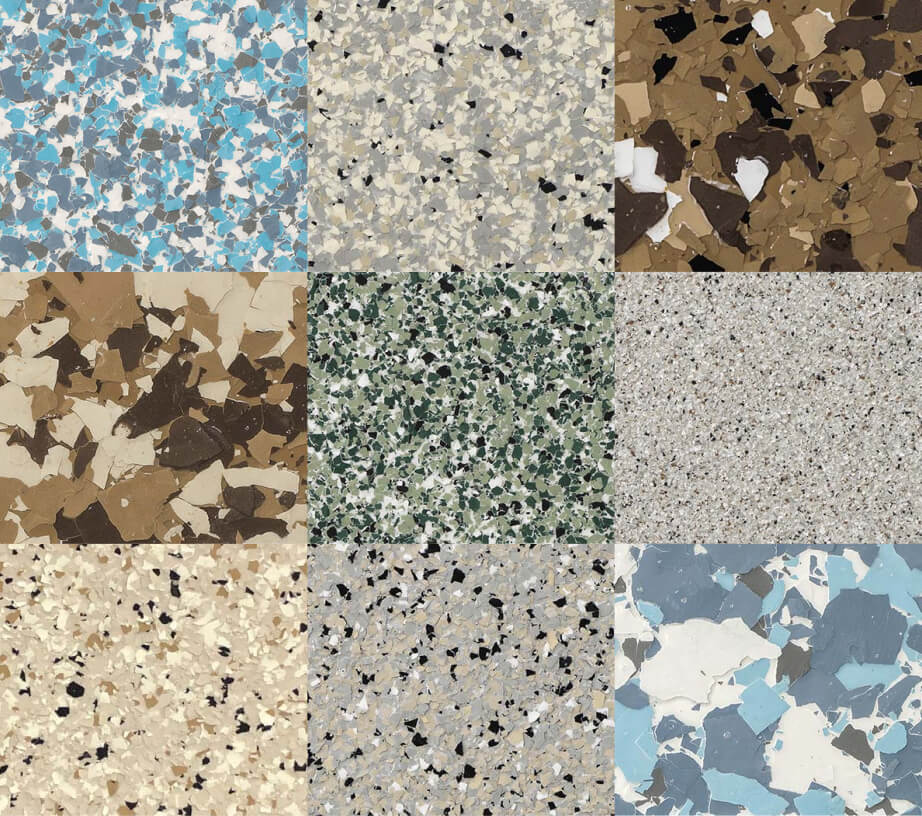

Epoxy concrete coatings are the most popular way to improve the appearance of your concrete floors while preserving their integrity for years to come. Available in solid colors or with decorative flakes, epoxy coatings provide your home or business with a customized look complete with a high-gloss finish.

Concrete Epoxy Coatings: The Benefits for Residential and Commercial Use

Epoxy, polyurea, and polyurethane coatings are exploding in popularity, and for good reason! These three concrete coatings– all available through MACH ONE™– are perfect for both residential and commercial applications. Some of the most notable benefits of concrete floor coatings include:

- Highly Durable

- Water, Chemical & Stain Resistant

- Quick Installation

- Aesthetically Pleasing

- Easy to Maintain & Clean

- Cost-Effective Flooring Solution

- Safe for Commercial Use

- Eco-Friendly

The most notable feature of these flooring solutions is their durability. Whether you’re looking for the ideal garage floor coating or a warehouse floor coating that can withstand heavy traffic and machinery, you need concrete coatings by MACH ONE™.

Alternatives: Polyurea and Polyaspartic Floor Coatings

Although epoxy is the most well-known concrete coating solution, it’s not necessarily for every application. In some cases, MACH ONE™ can recommend a polyaspartic or polyurea floor coating instead of epoxy. Some reasons we offer these coatings instead of epoxy include:

- Rapid dry time

- Shorter installation and cure times

- Allows faster return to service

Wondering what the best coating for your garage or concrete floors? Contact MACH ONE™ Epoxy Floors today! We’ll provide you with a free consultation and help you determine what material is right for your home, business, or warehouse. Request a quote today to get started!