When it comes to choosing a floor for your factory, you need something that can withstand scuffs, spills, abrasions, and heavy traffic. That’s why more and more manufacturing plants and factories are opting for concrete coatings like epoxy, polyurea, and polyaspartic. All three floor coatings are fantastic options for industrial facilities looking for a low-maintenance way to preserve their concrete floors.

Choosing a Factory Floor Coating: Epoxy, Polyaspartic, or Polyurea

Most facility managers have heard about epoxy floors; however, MACH ONE typically recommends polyaspartic or polyurea for manufacturing facilities for two primary reasons: strength and cure times.

Both polyaspartic and polyurea are stronger than epoxy, but equally as cost-effective. Because your factory has heavy machinery, equipment, and inventory moving throughout it daily, it’s important to install the most durable flooring system available. These two materials are abrasion, stain, and chemical resistant.

Polyurea and polyaspartic also cure more quickly than epoxy coatings, meaning less downtime for your operations.

The Flooring Installation Process for Manufacturing Plants

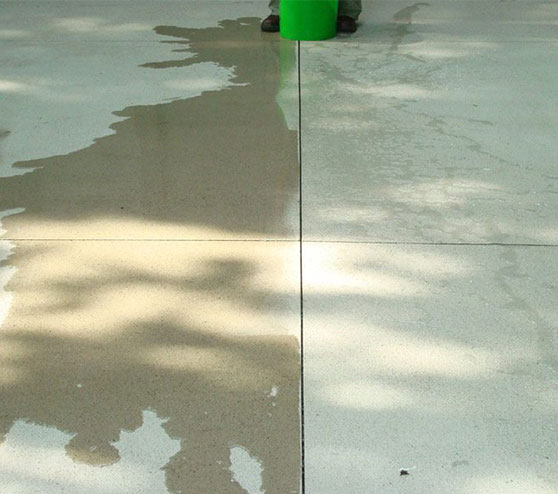

Whether our crew is working on a small project like a garage floor, or a large industrial project like a factory, we use the same industry-leading grinders and shot blasters to prep the concrete surface. By grinding and/or shot blasting the concrete floors, we expose the pores, making it possible for the coating to bond to the concrete. This preparation work also helps to level off imperfections and hide repairs.

Wondering whether or not we have what it takes to complete your job? You can rest assured our grinding machine is well-equipped to handle even the most enormous facilities. Weighing almost 1,000 lbs and equipped with head pressure of up to 440 lbs, we nickname this machine “The Beast.” As you might image, this machine can kick up quite a bit of dust which is why we utilize super-sized vacuums throughout the prep process. Our vacs are equipped with High Efficiency Particulate Absorbing (HEPA) filters, allowing us to minimize dust in your facility as much as possible.

Next, it’s time to apply your polyurea, polyaspartic, or epoxy floor coating. The application will vary some depending on the style and finish that you select. Ultimately, we will apply either a neat coat or base case to the concrete surface. If you’ve opted for a decorative finish like flakes, we will add them once the coating is applied. Finally, our crew will finish the application process with a high-quality top coat to seal the new installation.

Ready to learn more about industrial floor coatings for factories and manufacturing plants? Contact the coating contractors at your local MACH ONE! We will be happy to visit your facility and provide you with a free quote on coating services.